Havelock House 30 Timbercroft Ewell Surrey England KT 19 0TD

020 8786 8828

Integrated Systems to deal with multiple approvals - Quality, Environmental, Security, H&S

We can offer integrated solution where there is one system dealing with all subjects and/or improvements in a specific area:-

Developing Quality, Environmental, Security and Business Management Systems

Obtaining Approvals such as ISO 9001, ISO 14001, ISO 27001

Sector schemes - e.g. software systems such as TickIT, TickitPlus, construction systems such as Achilles Link-up and Achilles Building ConfidenceWe can help:-

Produce all the documentation, introduce the systems, deal with the assessment and maintain the approval - everything to make things happen

Help you change the culture, not just the documentation.

Guaranteed success with a 100% pass rate over 20 years

Provide fixed price solutions with no hidden costsSpecialised help includes:-

Total Quality Management (TQM)

Improvement Schemes

We offer part time staff to deal with all the approvals under our Shared Quality Manager Scheme to deal with all aspects of the work

National Quality and Reliability year sounds like part of the DTI's Quality

Initiative for the Y2000, in reality it was part of a mid 1960's quality promotion.

So what went wrong, why, over thirty years later are we still trying to hammer

home the message of quality?

One of the major problems is that we have not paid sufficient attention to

the real source of the quality, people. Rarely in my experience is the solution

to a product-based fault, either hardware or software, outside the realms

or the skills of the people employed by the company. My main job in problem

solving has been to provide the means of communication, getting the right

people together or at times acting as a messenger boy where communication

has completely broken down. If quality is to retain the level of attention

and importance it is currently receiving we need to be realistic about the

environment we work in and how we can bring about change within that organisation.

Understanding the Organisation

Firstly there is a need to understand the organisation within which you work

and where the company stands in its development. Most organisations will start

by being led by a strong forceful character who expects and gets his own way,

who is always right even when he is wrong and has an uncanny instinct for

survival. If he or she is no longer around, the culture created will still

be remembered and form part of the folk law and affect attitudes within the

company. Without this sort of character the company would not have grown but

there comes a time when this type of control is no longer possible or appropriate.

The size of the company may have outgrown the ability of the person to control

or he may have left or retired or just pressures from within the organisation

may have forced him to change. One company I recently worked with had just

this problem where many of the managers were still seeking the autocratic

approach they had grown up with.

The second stage of development is where the organisation has become bureaucratic

and built rules and procedures to control departments and individuals. Here

the demarcation lines between departments are more clearly defined and people

are more accountable for their actions. This is often the time when Quality

Systems such as ISO 9000 are built and thrive. These procedures which have

helped the company to survive may ultimately be the cause of its failure,

the bureaucracy and red tape stifling innovation and preventing change and

improvement.

The third stage is a democratic stage where people feel secure and confident

and the company structure and procedures provide a basic framework within

which individuals can work and impose their own personal style. Managers are

less protective of their empire and barriers between departments are more

easily crossed. This is the stage that correlates best with the teaching of

the Gurus and Total Quality Management.

Barriers to Improvement

I would be surprised if any of the readers of this article had not hit barriers

to improvement. The manager who sends you on a course and now is not interested

in you implementing anything you have learnt, the proposal you write which

every one agrees with but does not do anything about, the thousand and one

reasons why things are not as you see them. If you haven't failed you haven't

tried. These barriers are not just within the management but within all the

people you come in contact with and yourself. It may be that the person has

tried and failed, they perceive a threat to themselves or their empire, lack

confidence, experience or knowledge or possess a basic distrust of the system

or your motives.

This is the background against which any person involved in quality who wants

to make improvements has to survive and succeed. Some of the important tools

to the Quality Manager such as audits, conformance checks, statistics and

quality costs are often used without consideration as to whether it is the

right way or the time for the people involved. Within each of these subjects

there is a temptation to overlook the people and their ability to cause mayhem

in a theoretically perfect system. I remember well an occasion when an internal

audit prior to a customer assessment found over one hundred deficiencies.

It was obvious the division had problems before the audit, the audit just

consumed time and tied up people whose time could be better spent. The only

department that did well in the customer assessment was the Internal Audit

section but they won few friends and no lasting improvements. In recent months

I have read several articles on Total Quality, which have developed the idea

of internal customers, describing it as a process of controlling inputs and

outputs as if the people involved once programmed would turn out a quality

product each time, it is not that simple and will result in failure.

Getting to know the Individuals

As a Quality Manager or a manager involved in change, sitting in an office

and waiting for people to involve you or burying yourself in paperwork will

help no-one. Draw up a pie chart on how you spend your time, if a significant

proportion is not an involvement with other departments you are unlikely to

be effectively involved in improvement. You need to get out of your office

and meet people. Who do you talk to? No one, you listen to everyone. You will

need to start at the top, and understand the management's intended culture,

strategy and direction, then work down through the organisation and see how

well it is understood and works. It may be impossible to meet and know everyone

and at the lower levels you may need to create opportunities for people to

talk. Coffee machines are great places to find out what is happening. Equipment

about to be delivered, software acceptance tests and demonstrations are occasions

when you can show pleasure at the results achieved and in return be told the

problems and frustrations which needed to be overcome. Remember it is normally

the people at the bottom of the family tree who produce the product the customer

receives and upon whom quality will ultimately depend, all the rest of the

company provides support services to make the job "easier".

Getting to know and understand the organisation will take time but from the

first meeting you will need to be making judgements as to who is important

to you. You will need people at all levels who are at the extremes, those

who are in favour of change and are seeking a "Knight in shining armour"

to lead them forward, they provide a testing ground for your thoughts and

ideas and a safe haven when the going gets tough, but beware of ideas too

readily accepted. You also need the opposite extreme the people you expect

to fight the change you seek, you need to understand their view, they may

be right. The moaners and groaners, the silent people who never seem to hold

a view, these are likely to remain misfits but they often provide gems, although

the right course may be in the opposite direction. You will need people at

all levels from the boardroom to the most junior employee. Revolution starts

with belief and a small group of people.

The academics talk of the seven steps to Total Quality, I prefer to think

of them as the thousand and one steps towards quality. Not all steps will

be forward, for example you may increase inspection in an area, when your

long-term objective is to eliminate all inspection, or agree to a new standard

which has only minor improvements. Lots of small changes soon add up and are

easier to achieve. It is essential that people who make improvements no matter

how small are encouraged and not buried in a plethora of new suggestions.

Do not expect the changes introduced to follow a nice smooth curve, constant

change is something you see from the top of an ivory tower. At the bottom

the catastrophe theorem applies where an event will cause sudden and a significant

amount of change in a short period. For example a new manager, the start of

a new project or when something goes wrong. Learn to spot these opportunities

to get the maximum possible improvement.

You will need to be seen to do something, not just talk about it, so what

do you do and when. That will depend a lot on the organisation and what it

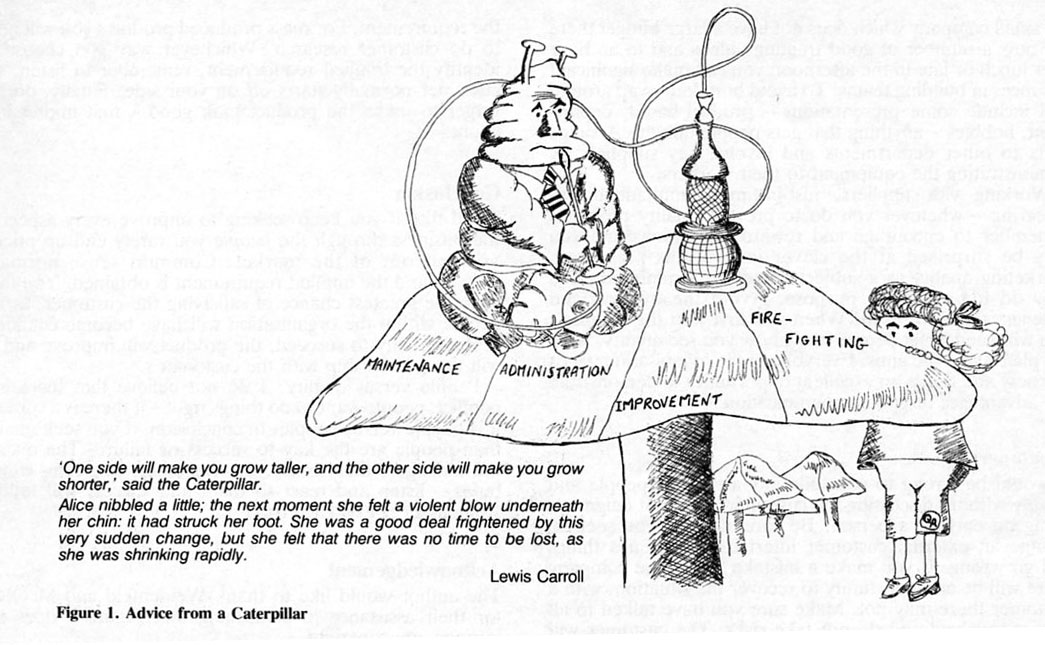

perceives to be its quality problems. Doodle with the pie chart, how much

time do you spend in the four categories, fire fighting, administration, maintenance

and improvement.

.

Fire Fighting

At first you must give priority to fire fighting. The problems will have

put management under pressure and you will need to demonstrate you are, in

the short term, useful to the organisation. You also need to gain some respect

and help create time for people to look at the long-term solution.

In my younger days I would have analysed the problem and made a judgement

on its importance to the company. Trivial or complete misunderstandings of

the situation would have been quickly discarded. This alienated people from

me, I had failed to do anything about something they considered important,

I had belittled them. Solving lots of these minor problems and considering

each important will help to get people marketing quality for you by telling

others of the improvements that are happening. Lead by example but beware

of becoming the chief fire fighter. Your job is to get as many members of

the company believing in their ability to solve problems and make improvements

as possible. You will find a few major problems, probably of a technical nature,

it is essential that on these occasions leadership comes from the top through

the direct lines of management. You may be a part of the team, you certainly

need to know what is happening but make sure ownership is in the right place.

Support, help, be ready to pick up the pieces and get corrective action into

the system but don't take over.

Administration

Administration activities are the tasks associated with the day to day management

of your department and the staff and any other work of a non-quality nature.

I understand that traditionally having a large budget brings power and status

but for a Quality Manager it will ultimately work against you. Time spent

improving your department's performance is time you are not available to improve

the company's quality.

Maintenance

Maintenance is the time you spend checking that the areas, which have made

improvements, are not sliding backwards. For example, attend design reviews,

acceptance tests or look at deliverable equipment and undertake audits. Do

not expect every change to stick first time, sometimes you will go back and

find things just as they were before you started. Then you need to try again

or find another way of solving the problem. Check by talking and listening

to people again.

Writing procedures is one of the main maintenance activities. The procedures

for the company must have quality built into them, not a separate chapter

or volume. Ownership for all aspects of quality must be with the department

managers. Realistically, despite all the documentation, Quality is still dependent

on the skill and expertise of the people. Procedure writing is often seen

as an improvement not a maintenance activity, but it is not, it can only retain

the status quo. People discussing new ways of working or working in accordance

with the procedures or training based on the procedures should prevent problems

but rarely will the documenting of the procedure prevent anything. People

will still ask or tell others how to do something and if you send them off

to read the procedure they will still come back and ask "but what if

this" or "do I really need to, if I am just", they want and

need the personal involvement in what they are doing. The procedures are essential

to a developing organisation or one that has to demonstrate to a third party

that they have a system, but so often the documents produced just become dust

collectors and door stops. Hopefully Information Technology systems will make

it easier to demonstrate that quality is inherent in the system and reduce

some of the bureaucracy.

Improvement

Improvement is the last part of your pie chart and your aim will always

be to increase the proportion of your time spent on this subject. Priority

must be given to obtaining commitment to change from the top, but do not expect

your ideas to be seen as the best thing since sliced bread. You will need

to persevere, they are people and will need to be convinced. They will also

want the change to be at their rate and under their control.

The right tools and equipment for the job must be a prime consideration and

it is important that the people who will use the equipment are involved in

the selection. In one manufacturing area I was helping improve, the operators

were using soldering iron bits that were worn out. The company culture was

concerned with saving money and the soldering bits were locked in the charge-hands

drawers and the issue carefully controlled. This was soon changed but the

real point of the story is that in the corner was a wave soldering machine,

two years old and never used. The management and engineering team had worked

hard to obtain approval for the purchase, carefully studying the market but

totally forgetting to involve or seek the views of the people who were going

to use the equipment. The machine stood as a permanent example of the "management's"

wastefulness. The machine was sold for peanuts and the loss far exceeded the

saving being made on soldering bits, even without considering printed circuit

board reliability.

Changing People

"If you can't change the people, change the people" is one of

those fashionable phrases with which I disagree. For anyone but a psychologist

to try and change a person is arrogant and wrong. The objective is to bring

out the best in people, get them to see things from a different perspective.

People are the most important resource the company has, the investment in

recruitment and the time taken to become an effective member of the team is

high, it should not be squandered. You will need to make sure the management

have the skills to know when to give clear directions, when to explain why

they are doing something, the times when people need support and when they

are able to delegate. Sometimes people will be in the wrong job and then you

need to be honest and make sure that help is provided to find new work. It

is worth noting that Ian McGregor brought about the change from loss to profit

in the steel industry using the management he inherited. What he provided

was the leadership and direction. This must be a lesson we can all learn from.

Communication

We have talked about classical tools for the worker but this is not the

key issue, the area where most companies need to improve is communication.

People need to be trained to communicate and to learn how to work together

as a team. I have already talked about the person returning from a training

course to find himself out of phase, this is a real danger and one of the

reasons I favour internal training. For the small company who does not have

a large budget there are now a number of good training videos and in an hour

over lunch or late in the afternoon you can make significant advances in building

teams. To avoid boredom swap around and include some presentations, product

based, department, hobbies anything that gets people talking. Arrange visits

to other departments and involve key suppliers by demonstrating the equipment

to their workers.

Working with suppliers, Just-In-Time, Simultaneous Engineering what ever you

do to prevent quality problems remember to encourage and reward suggestions

and you may be surprised at the clever innovations presented. Marketing quality

as a subject I keep to a minimum and only do for a specific purpose, avoid

the oversell and staleness that can result. When you first join the company

you will need to let people know how you see quality, what the plan is and

the aims. Everyone in the organisation needs to know and this is an excellent

opportunity to demonstrate the advantages of good communication.

Customers

It would be wrong to conclude any article on people and quality without

discussing the customer, the most enigmatic being on earth, a person. Be careful

when you seek to change an external customer interface, sometimes things will

go wrong. If you make a mistake within the company there will be an opportunity

to recover the situation, with a customer there may not. Make sure you have

talked to all parties involved and do not take risks. The customer will have

similar personal barriers to those described earlier and preconceived ideas

on how a customer should be treated. He may also have pressures from his own

management. Have you ever been sent back to get another half percent off an

order or with another question you do not feel comfortable asking. Think how

you feel as a customer.

The requirement specification for my latest car was that it must be red (the

wife's input) and for me that it must be a popular British make, so all the

faults have been found by others. We chose one that had an extra two inches

in the back for the children. In retrospect I should have undertaken a product

audit on the plastic mouldings as they all broke. For the service industry

such as hotels the requirement may be just stated as the duration of the stay,

number of beds and meals. In the examples the quality of the product is implied

not stated, this applies equally to technical products. Your company is the

experts and to expect the customer to have the knowledge to fully define the

requirements is wrong. There may be a stage of discussion with the customer

where the requirement is clarified and documented but this will only cover

the major points otherwise the profit would disappear in the writing of the

requirement. For mass production products you will need to do customer research.

Whichever way you choose to identify the implied requirements remember to

listen, the customer normally starts off on your side. Finally do not forget

to make the product look good, first impressions count.

Conclusion

I find that if you keep seeking to improve every aspect of the business

through the people you rarely end up pricing yourself out of the market, common

sense normally prevails and the implied requirement is obtained. You then

have the greatest chance of satisfying the customer as the people within the

organisation will have become confident in their ability to succeed, the product

will improve and the relationship with the customer.

Quality versus People? I do not believe it is, people want to do things right,

if there is a conflict it is people v people. In conclusion if you seek quality

then people are the key to success or failure. The owner, the manager, the

worker, the customer, everyone contributes, listen and react to them and success

will follow. Remember People First.